high quality warman slurry pump drawings

Latest articles

Slurry Pump

high quality warman slurry pump drawings...

high quality warman slurry pump drawings 【high quality warman slurry pump drawings】

Read MoreA slurry is a mixture of fluids, which consists of a water-like liquid and particles. Typically, slurry acts in the same way as a viscous, sticky fluid - moving with gravity - but usually needs to be pumped.

high quality warman slurry pump drawings...

high quality warman slurry pump drawings 【high quality warman slurry pump drawings】

Read MorePumping slurry can be a challenging problem, but with the right instruction, pumping and maintenance plan, you will achieve operational success.

high quality warman slurry pump drawings...

high quality warman slurry pump drawings 【high quality warman slurry pump drawings】

Read MoreSlurry pipe diameter.

high quality warman slurry pump drawings...

high quality warman slurry pump drawings 【high quality warman slurry pump drawings】

Read MoreWY type pump casing is made of abrasion resistant metal, impeller material can be abrasion resistant metal or rubber. The submerged parts of WYJ are all lined with rubber, for transfer corrosive slurry.

high quality warman slurry pump drawings...

high quality warman slurry pump drawings 【high quality warman slurry pump drawings】

Read MoreA slurry is any mixture of a fluid (such as water) and a powdery solid. Slurries are used as a convenient way to handle bulk solids in the mining, steel processing, foundry, power generation and, more recently, frac sand mining industries. Slurries typically behave like viscous viscous fluids, flowing under gravity, but can also be pumped as needed.

high quality warman slurry pump drawings...

high quality warman slurry pump drawings 【high quality warman slurry pump drawings】

Read MoreCompared to standard centrifugal pumps, centrifugal pumps optimized for slurry pumping typically have the following features.

high quality warman slurry pump drawings...

high quality warman slurry pump drawings 【high quality warman slurry pump drawings】

Read MoreMaterials of Construction

high quality warman slurry pump drawings...

high quality warman slurry pump drawings 【high quality warman slurry pump drawings】

Read MoreIn this article, we will present practical guidelines and rules for slurry centrifugal pumps. We will also discuss key operating characteristics, material selection and other considerations.

high quality warman slurry pump drawings...

high quality warman slurry pump drawings 【high quality warman slurry pump drawings】

Read MorePumping slurry can present some challenges and problems, but with proper engineering and equipment selection, you can experience years of trouble-free operation. It's important to work with a qualified engineer when selecting a slurry pump, because slurry can wreak havoc on a pump if not selected properly.

high quality warman slurry pump drawings...

high quality warman slurry pump drawings 【high quality warman slurry pump drawings】

Read More

Popular articles

- Some models can generate discharge pressures up to 260 ft. (80 m).

- Light-duty Slurry Pump

- The discharge branch can be positioned at intervals of 45 degrees by request and oriented to any eight positions to suit installations and applications. There are many drive modes for option, such as V-belt, flexible coupling, gearbox, hydraulic coupler variable frequency, silicon controlled speed, etc. Among them, the flexible shaft coupling drive and V-belt feature of low cost and easy installation.

- Horizontal centrifugal pumps are commonly used for slurry service, but vertical and other types of pumps are better suited to certain specific applications. Centrifugal pumps for handling slurries have features tailored to specific services that reflect the corrosive or abrasive nature of the slurry and the concentration of solids. These may include the choice of materials, the use of liners or even different drive sizes.

- Slurry Pump

- A quench plan, as the name indicates, is designed to quench or cool the seal. It is normally used if short periods of dry running are expected. As illustrated bellow, the fluid is introduced into the area between the back of the seal faces and the close fit exit on the drive side of the pump.

Latest articles

-

3.Basic pump components such as impeller size and design, materials of construction and discharge configuration must be considered to ensure that the pump can withstand the wear and tear caused by abrasive slurries. Slurry pumps are typically larger in size compared to low viscosity liquid pumps and often require more horsepower to operate due to their lower efficiency. Bearings and shafts must also be more robust and durable.

-

Submersible Slurry Pump

-

Fewer and thicker vanes on the impeller. This makes it easier for solids to pass through than the 5-9 vanes on a standard centrifugal pump - typically 2-5 vanes.

-

The mud pump is the motor driving the piston move through the link mechanism. Then causes the change of the volume of the sealed chamber of the mud pump. and the pressure difference between inside and outside of the pump change. Finally, the process of absorbing water and draining water is complete.

-

Determine the operating parameters of the pump.

-

>Slurry Pump

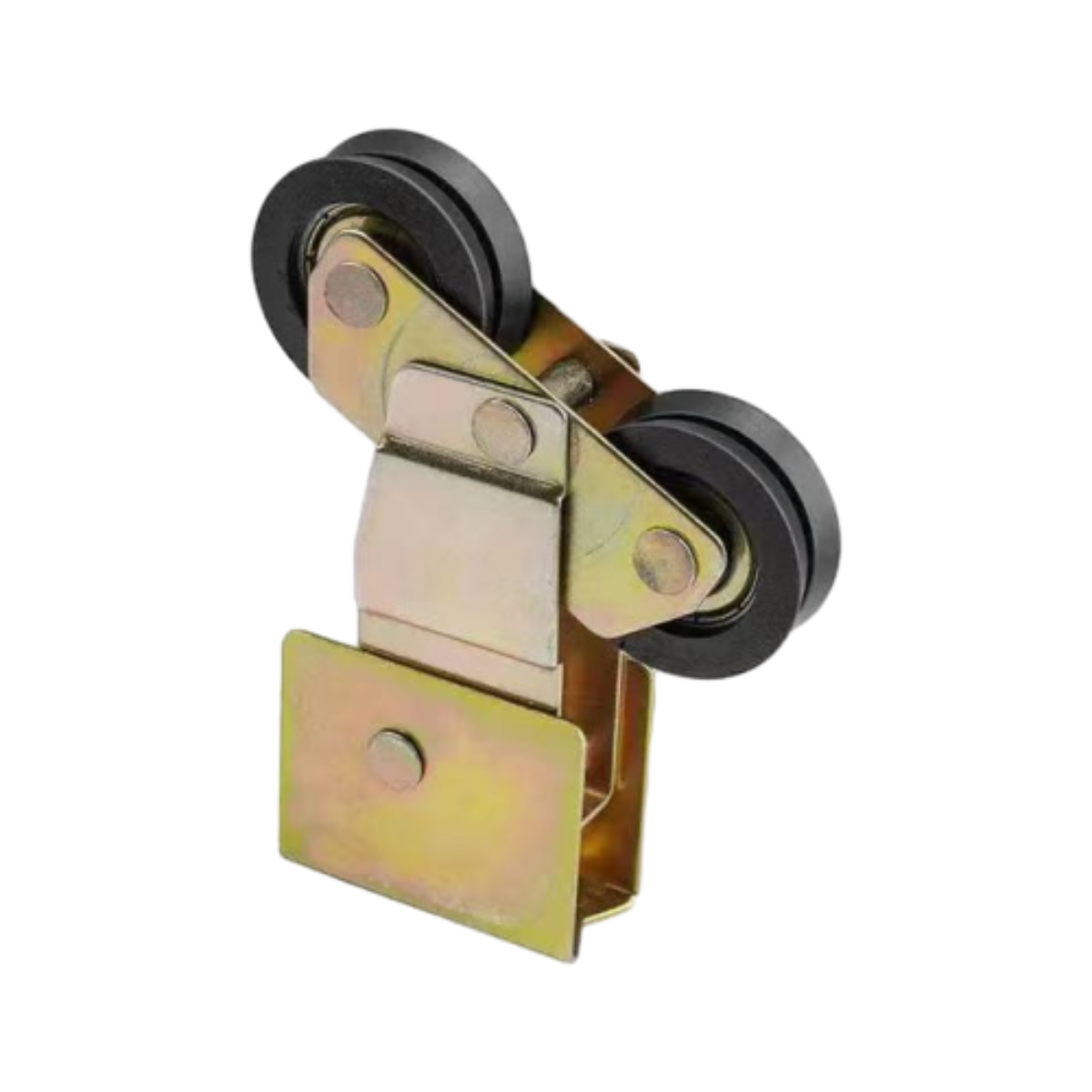

To ensure that the rollers of your aluminum sliding windows remain in good working condition, regular maintenance is essential

. Here are some tips metal storage box with lock. Many models come with handles or wheels, making it easy to move the box from one location to another. This is especially useful if you need to transport your valuables to a different place, such as a safety deposit box at a bank or a safe deposit box rental facility.

metal storage box with lock. Many models come with handles or wheels, making it easy to move the box from one location to another. This is especially useful if you need to transport your valuables to a different place, such as a safety deposit box at a bank or a safe deposit box rental facility.Colour

Anodised Aluminium Profiles

For those with a creative knack, wrought iron can be shaped into intricate designs that reflect personal style and enhance the home’s decor.

They are typically easy to install, often requiring just a few screws to attach them securely to the wall They are typically easy to install, often requiring just a few screws to attach them securely to the wall

They are typically easy to install, often requiring just a few screws to attach them securely to the wall They are typically easy to install, often requiring just a few screws to attach them securely to the wall steel thermostat lock box. Once in place, accessing the thermostat remains straightforward, ensuring you can still make necessary adjustments without hassle.

steel thermostat lock box. Once in place, accessing the thermostat remains straightforward, ensuring you can still make necessary adjustments without hassle.One of the most frequent questions I get as a fence designer is whether to install either a wrought iron or aluminum fence. Both are great fencing materials and both will do the job of providing a highly secure perimeter for your home or commercial property. However, there are some distinct differences between the two fence materials worth considering before making a final decision. I hope that this explanation of their differences will help!

They provide a secure seal around the edge of the window or door, preventing any drafts or leaks from entering the building They provide a secure seal around the edge of the window or door, preventing any drafts or leaks from entering the building

They provide a secure seal around the edge of the window or door, preventing any drafts or leaks from entering the building They provide a secure seal around the edge of the window or door, preventing any drafts or leaks from entering the building aluminium glazing bead profiles. This not only enhances the energy efficiency of the property but also improves the overall comfort and safety of the interior space.

aluminium glazing bead profiles. This not only enhances the energy efficiency of the property but also improves the overall comfort and safety of the interior space.Lubricate the window’s moving parts routinely: The hinges and locks of old windows might experience unnecessary wear and tear over time, making them difficult to use and stiffer. Apply a lubricant that contains silicone to the moving elements to avoid this from happening. Simply add a very tiny amount of lubricant to the hinges and locks, and then open and close the door a few times to work the oil into the hinges and locks.